Micro-alloyed forging steels

ORI Martin produces micro-alloyed steel obtained through rolling at a controlled temperature, able to guarantee homogeneous structures and high performance on the finished product.

Steel grade

| Steel grade | Corresponding standard | Average chemical composition | ||||||

|---|---|---|---|---|---|---|---|---|

| C | Mn | Si | S | V | ||||

| MnV | 20MnV6 | 1.5217 | C20MV6L | 0,19 | 1,50 | - | 0,04 | 0,15 |

| 30MnVS6 | 1.1302 | B30MV6L | 0,29 | 1,40 | - | 0,04 | 0,16 | |

| 38MnVS6 | 1.1303 | B38MV6L | 0,38 | 1,40 | - | 0,04 | 0,16 | |

| 46MnVS6 | 1.1304 | 0,46 | 1,40 | - | 0,04 | 0,16 | ||

| 46MnVS3 | 1.1305 | 0,46 | 0,80 | - | 0,04 | 0,16 | ||

| 55MnV6 | 0,55 | 0,85 | 0,20 | - | 0,15 | |||

Products

Wire rod

Rolling takes place at a controlled temperature using the very latest technology. This allows a smaller grain size to be obtained together with a more fine and even structure. Optimal characteristics for subsequent use in drawing and cold moulding in addition to a higher degree of globularisation after the annealing process.

Rolling takes place at a controlled temperature using the very latest technology. This allows a smaller grain size to be obtained together with a more fine and even structure. Optimal characteristics for subsequent use in drawing and cold moulding in addition to a higher degree of globularisation after the annealing process.

Hot rolled bars

Production takes place in a rolling mill at a controlled temperature using the very latest technology which guarantees a fine grain and homogeneous structure; the calibrator finishing block allows bars with restricted dimensional tolerances.

Production takes place in a rolling mill at a controlled temperature using the very latest technology which guarantees a fine grain and homogeneous structure; the calibrator finishing block allows bars with restricted dimensional tolerances.

Sales: ORI Martin S.p.A.

Sales: ORI Martin France Sarl

Sales: ORI Martin Deutschland GmbH

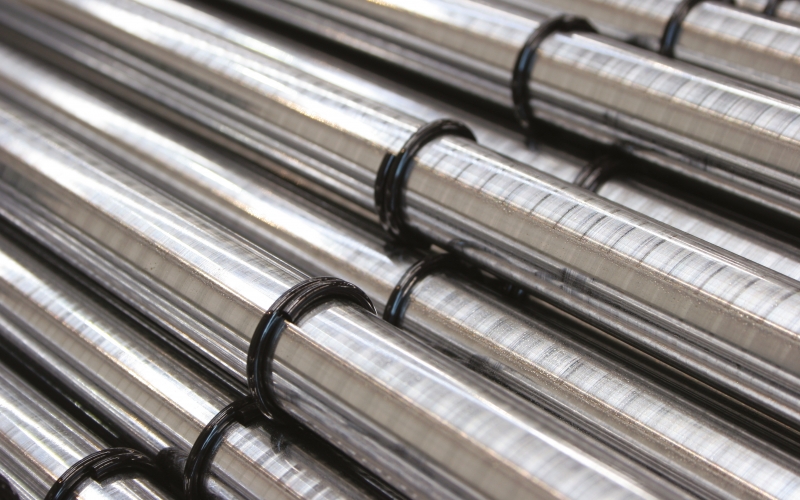

Peeled bars

Peeled bars from 17 to 80 mm.

Peeled bars from hot rolled bars can be produced with the following additional operations and controls:

- Heat treatment by annealing (soft and spheroidized annealing and so on)

- Heat treatment by quenching and tempering, normalising or stress reliving by induction

- Ends chamfering

- Surface defect control by Eddy Current

- Anti-mixing control

- Ultrasonic test

Peeled bars from hot rolled coil can be produced with the following additional operations and controls:

- Heat treatment by annealing (soft and spheroidized annealing and so on)

- Heat treatment by quenching and tempering, normalising or stress reliving by induction (after peeling)

- Ends chamfering

- Surface defect control by Eddy Current

- Anti-mixing control

Peeled bars from 17 to 80 mm.

Peeled bars from hot rolled bars can be produced with the following additional operations and controls:

- Heat treatment by annealing (soft and spheroidized annealing and so on)

- Heat treatment by quenching and tempering, normalising or stress reliving by induction

- Ends chamfering

- Surface defect control by Eddy Current

- Anti-mixing control

- Ultrasonic test

Peeled bars from hot rolled coil can be produced with the following additional operations and controls:

- Heat treatment by annealing (soft and spheroidized annealing and so on)

- Heat treatment by quenching and tempering, normalising or stress reliving by induction (after peeling)

- Ends chamfering

- Surface defect control by Eddy Current

- Anti-mixing control

Sales: Trafilati Martin Srl

Peeled & reeled bars

Peeled & reeled bars (+SH EN 10277)

Alloy Steel, Non-Alloy Steel and Stainless Steel

Ø 10,00 ÷ 200,00 ( ≥IT9 ) EN 10278

Peeled & reeled bars (+SH EN 10277)

Alloy Steel, Non-Alloy Steel and Stainless Steel

Ø 10,00 ÷ 200,00 ( ≥IT9 ) EN 10278