Post-Tension Systems

T.T.M. S.r.l. proposes to the construction and design of the various system solutions for post tension, bridges/viaducts, tanks and slabs.

All Bonded and Unbonded systems are produced in compliance with the guideline ETAG013, guaranteed over time and to ensure safe use in prestressed concrete structural elements and are in accordance with ETA.

The anchorages are tested and qualified to provide high fatigue resistance and durability.

The production of post tension anchors protected against corrosion is one of the main products offered today to structural engineering. These solutions are designed to offer high protection anchors over time, ensuring it by infiltrations or corrosive environments.

The system includes the use of the strand 7-wire in three types, Normal, Super and Compact.

The use of the strand T15C (Compact) with diameter and section respectively of 15.2 mm and 165 mm², allows to reduce the dimensions, by applying anchorages of smaller dimensions thus also reducing the size of the tensioning jacks.

The availability of steel strand is guaranteed by the ability of the Group, with two manufacturing facilities with an annual capacity of 150,000 tons.

T.T.M. S.r.l. proposes to the construction and design of the various system solutions for post tension, bridges/viaducts, tanks and slabs.

All Bonded and Unbonded systems are produced in compliance with the guideline ETAG013, guaranteed over time and to ensure safe use in prestressed concrete structural elements and are in accordance with ETA.

The anchorages are tested and qualified to provide high fatigue resistance and durability.

The production of post tension anchors protected against corrosion is one of the main products offered today to structural engineering. These solutions are designed to offer high protection anchors over time, ensuring it by infiltrations or corrosive environments.

The system includes the use of the strand 7-wire in three types, Normal, Super and Compact.

The use of the strand T15C (Compact) with diameter and section respectively of 15.2 mm and 165 mm², allows to reduce the dimensions, by applying anchorages of smaller dimensions thus also reducing the size of the tensioning jacks.

The availability of steel strand is guaranteed by the ability of the Group, with two manufacturing facilities with an annual capacity of 150,000 tons.

Mono Strand

The new architectural and structural needs require technological solutions with devices that are able to guarantee a high performance to comply with: ETAG013 guidelines, traceability, easy assembly, durability and resistance against corrosion.

Post-tensioning allows building structures with greater spans and reduced structural beam depths, resulting in larger column-free areas. As a result, internal layouts are not limited by tight columns grids.

The deformation and crack control are some of the aspects that are effectively controlled by the application of cables, in spite of the conventional reinforced concrete structures.

Slab post-tensioning can include bonded as well as unbonded post-tensioning systems.

Bonded systems are carried out with wire strands wrapped in metallic or polyethylene sheaths, provided with grout and vent to allow a correct filling of the cables with cement.

Unbonded systems are carried out with wire strands greased and covered in polyethylene (coated) which do not require any cement grouting.

For both systems, bonded and unbonded, tensioning is carried out strand by strand. Wire strands are then blocked on the active anchorage with a hydraulic locking of wedges on the anchorage.

Post-tensioning technology has been used for many years mainly to build big structures such as: bridges, beams, tanks, etc. Taking advantage of the application of concentrated loads, their capacity to react to loads without cracking the concrete was improved. Smaller structures were carried out using traditional systems, without taking into consideration the possibility to use post-tensioning applications, therefore: industrial floors, diaphragms slabs, foundation piles, which were normally produced with steel reinforcement only, now take great structural advantages of the application of post-tensioning.

The new architectural and structural needs require technological solutions with devices that are able to guarantee a high performance to comply with: ETAG013 guidelines, traceability, easy assembly, durability and resistance against corrosion.

Post-tensioning allows building structures with greater spans and reduced structural beam depths, resulting in larger column-free areas. As a result, internal layouts are not limited by tight columns grids.

The deformation and crack control are some of the aspects that are effectively controlled by the application of cables, in spite of the conventional reinforced concrete structures.

Slab post-tensioning can include bonded as well as unbonded post-tensioning systems.

Bonded systems are carried out with wire strands wrapped in metallic or polyethylene sheaths, provided with grout and vent to allow a correct filling of the cables with cement.

Unbonded systems are carried out with wire strands greased and covered in polyethylene (coated) which do not require any cement grouting.

For both systems, bonded and unbonded, tensioning is carried out strand by strand. Wire strands are then blocked on the active anchorage with a hydraulic locking of wedges on the anchorage.

Post-tensioning technology has been used for many years mainly to build big structures such as: bridges, beams, tanks, etc. Taking advantage of the application of concentrated loads, their capacity to react to loads without cracking the concrete was improved. Smaller structures were carried out using traditional systems, without taking into consideration the possibility to use post-tensioning applications, therefore: industrial floors, diaphragms slabs, foundation piles, which were normally produced with steel reinforcement only, now take great structural advantages of the application of post-tensioning.

Geotechnical

T.T.M. S.r.l. produces permanent and temporary ground anchors in compliance with the Ministerial Decree 14.01.2008 and Presidential Decree no. 12391 as of 22.12.2011 (guideline for the certification of the technical suitability for ground anchors for geotechnical applications). All the products also comply with the standard EN 1537-2013.

All the ground anchors can be installed with TTR-E and TTM anchorages and are made of wire strands in harmonic steel produced according to prEN 10138.

In order to guarantee a constant production over time and a quick service to customers, highly automatic plants were implemented to achieve a high level of production ensuring quality at the same time.

The production of ground anchors is developed over four lines. The whole production system has a daily capacity of cutting of about 80.000 meters of strands by means of extremely high productiveness numerical control plants.

An anchor consists of an anchor head, a free anchor length and a fixed anchor length.

Head: group of terminal elements that transmit the tensile load of the anchor to the anchored structure or directly to the rock;

Free length: group of elements that transmit the tensile load from the head to the foundation;

Foundation: group of elements that transmit the tensile load of the anchor to the ground.

T.T.M. S.r.l. produces permanent and temporary ground anchors in compliance with the Ministerial Decree 14.01.2008 and Presidential Decree no. 12391 as of 22.12.2011 (guideline for the certification of the technical suitability for ground anchors for geotechnical applications). All the products also comply with the standard EN 1537-2013.

All the ground anchors can be installed with TTR-E and TTM anchorages and are made of wire strands in harmonic steel produced according to prEN 10138.

In order to guarantee a constant production over time and a quick service to customers, highly automatic plants were implemented to achieve a high level of production ensuring quality at the same time.

The production of ground anchors is developed over four lines. The whole production system has a daily capacity of cutting of about 80.000 meters of strands by means of extremely high productiveness numerical control plants.

An anchor consists of an anchor head, a free anchor length and a fixed anchor length.

Head: group of terminal elements that transmit the tensile load of the anchor to the anchored structure or directly to the rock;

Free length: group of elements that transmit the tensile load from the head to the foundation;

Foundation: group of elements that transmit the tensile load of the anchor to the ground.

Equipment

All equipment is made in full respect of the Standard, therefore equipped with user manuals and maintenance, metal plate reporting the identification of the machine and the serial number.

All the machines are provided with on board electrical protections and are supplied as follows: 3 poles plus earth 3P+T with supply at 380 Volt. 50Hz. and 16, 32 and 63 Amp supply base on the machine absorption.

Where a direction of rotation must be observed, machines are provided with a change-over switch to allow the phase inversion automatically without any manual intervention on the circuit.

All the hydraulic circuits are provided with safety valves to limit overpressure or mistakes in the operation of regulation valves. A metallic label identifies the machine and its part number.

All the machines are provided with operating and maintenance manuals and with the CE marking upon request.

Our equipment’s:

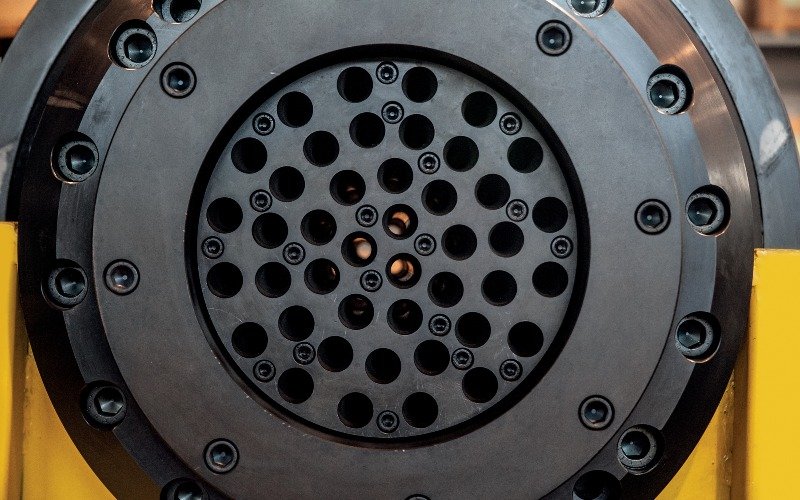

JACKS, available in different versions

HYDRAULIC PUMP, used for stressing operations

GROUTING PUMP, equipped with two tanks for the dough colloidal and as a reservoir

STRAND FORCING MACHINE, of different versions, that allows the insertion of the strand in to the sheath

All equipment is made in full respect of the Standard, therefore equipped with user manuals and maintenance, metal plate reporting the identification of the machine and the serial number.

All the machines are provided with on board electrical protections and are supplied as follows: 3 poles plus earth 3P+T with supply at 380 Volt. 50Hz. and 16, 32 and 63 Amp supply base on the machine absorption.

Where a direction of rotation must be observed, machines are provided with a change-over switch to allow the phase inversion automatically without any manual intervention on the circuit.

All the hydraulic circuits are provided with safety valves to limit overpressure or mistakes in the operation of regulation valves. A metallic label identifies the machine and its part number.

All the machines are provided with operating and maintenance manuals and with the CE marking upon request.

Our equipment’s:

JACKS, available in different versions

HYDRAULIC PUMP, used for stressing operations

GROUTING PUMP, equipped with two tanks for the dough colloidal and as a reservoir

STRAND FORCING MACHINE, of different versions, that allows the insertion of the strand in to the sheath