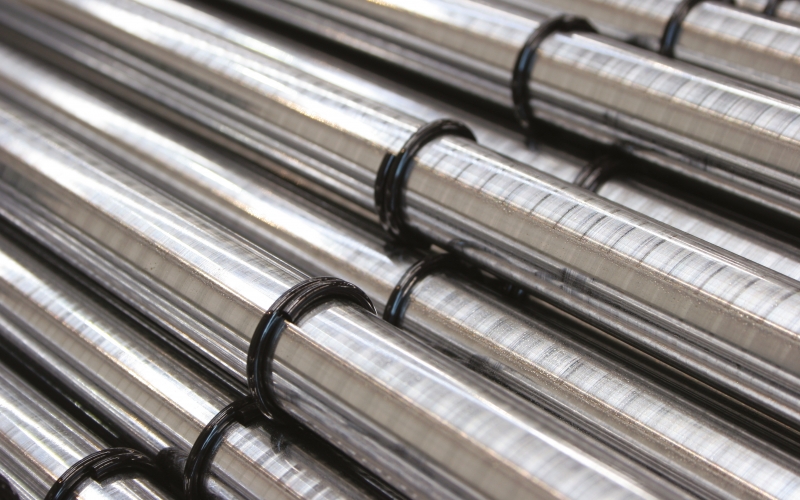

Cold drawn bars

Cold drawn bars are cold finished products achieved by the cold deformation of the wire rod through a die that reduces the diameter and after various controls are cut into the length required. This process achieves the calibration of the wire into the diameter required. We can obtain wire in a wide range of diameters, the mechanical characteristics increase depending on the reduction carried out.

Cold drawn bars can be produced with the following additional operations and controls:

- Heat treatment by annealing (soft and spheroidized annealing and so on)

- Heat treatment by quenching and tempering, normalising or stress reliving by induction (after drawing)

- Ends chamfering

- Surface defect control by Eddy Current

- Anti-mixing control

Cold drawn bars are cold finished products achieved by the cold deformation of the wire rod through a die that reduces the diameter and after various controls are cut into the length required. This process achieves the calibration of the wire into the diameter required. We can obtain wire in a wide range of diameters, the mechanical characteristics increase depending on the reduction carried out.

Cold drawn bars can be produced with the following additional operations and controls:

- Heat treatment by annealing (soft and spheroidized annealing and so on)

- Heat treatment by quenching and tempering, normalising or stress reliving by induction (after drawing)

- Ends chamfering

- Surface defect control by Eddy Current

- Anti-mixing control

Peeled bars

Peeled bars from 17 to 80 mm.

Peeled bars from hot rolled bars can be produced with the following additional operations and controls:

- Heat treatment by annealing (soft and spheroidized annealing and so on)

- Heat treatment by quenching and tempering, normalising or stress reliving by induction

- Ends chamfering

- Surface defect control by Eddy Current

- Anti-mixing control

- Ultrasonic test

Peeled bars from hot rolled coil can be produced with the following additional operations and controls:

- Heat treatment by annealing (soft and spheroidized annealing and so on)

- Heat treatment by quenching and tempering, normalising or stress reliving by induction (after peeling)

- Ends chamfering

- Surface defect control by Eddy Current

- Anti-mixing control

Peeled bars from 17 to 80 mm.

Peeled bars from hot rolled bars can be produced with the following additional operations and controls:

- Heat treatment by annealing (soft and spheroidized annealing and so on)

- Heat treatment by quenching and tempering, normalising or stress reliving by induction

- Ends chamfering

- Surface defect control by Eddy Current

- Anti-mixing control

- Ultrasonic test

Peeled bars from hot rolled coil can be produced with the following additional operations and controls:

- Heat treatment by annealing (soft and spheroidized annealing and so on)

- Heat treatment by quenching and tempering, normalising or stress reliving by induction (after peeling)

- Ends chamfering

- Surface defect control by Eddy Current

- Anti-mixing control

Turned by lathe bars

Trafilati Martin can produce via a free cutting numeric control process, cut bars to the clent's specification. Machineries are composed by Nakamura wt 250, Nakamura wt 150 e Gildemeister sprint 32.

Diameter Range: 52mm max

Trafilati Martin can produce via a free cutting numeric control process, cut bars to the clent's specification. Machineries are composed by Nakamura wt 250, Nakamura wt 150 e Gildemeister sprint 32.

Diameter Range: 52mm max

Gundrilled bars

Trafilati Martin is equipped with 11 drillers with the ‘gun-drilling’ system and machineries multi-function (ZIMAR, VENTURA, SIG) can produce pieces in small-medium series following specific request of the client.

Area of drilling: Diameter 2,50 - 28,00 mm.

Deepness max. hole: 1200 mm one side or both side

External diameter: Diameter 10 - 60 mm.

Trafilati Martin is equipped with 11 drillers with the ‘gun-drilling’ system and machineries multi-function (ZIMAR, VENTURA, SIG) can produce pieces in small-medium series following specific request of the client.

Area of drilling: Diameter 2,50 - 28,00 mm.

Deepness max. hole: 1200 mm one side or both side

External diameter: Diameter 10 - 60 mm.

Sales: Trafilati Martin Srl

Peeled & reeled bars

Peeled & reeled bars (+SH EN 10277)

Alloy Steel, Non-Alloy Steel and Stainless Steel

Ø 10,00 ÷ 200,00 ( ≥IT9 ) EN 10278

Peeled & reeled bars (+SH EN 10277)

Alloy Steel, Non-Alloy Steel and Stainless Steel

Ø 10,00 ÷ 200,00 ( ≥IT9 ) EN 10278

Cold drawn bars

Cold drawn bars (+C EN 10277)

Alloy Steel, Non-Alloy Steel and Stainless Steel

Ø 8,00 ÷ 74,00 ( ≥IT9 ) EN 10278

Cold drawn bars (+C EN 10277)

Alloy Steel, Non-Alloy Steel and Stainless Steel

Ø 8,00 ÷ 74,00 ( ≥IT9 ) EN 10278

Ground Bars

Ground bars

Alloy Steel, Non-Alloy Steel and Stainless Steel

Ø 6,00 ÷ 200,00 (IT9 ÷ IT6) EN 10278

Ground bars

Alloy Steel, Non-Alloy Steel and Stainless Steel

Ø 6,00 ÷ 200,00 (IT9 ÷ IT6) EN 10278

Sales: Novacciai Martin Srl

Medium-High carbon wire

Drawn wire is produced in the SLM facility for medium to high carbon springs for applications in the mechanical spring sector.

Diameter Range: Ø from 1,30 mm up to 12,00 mm

Drawn wire is produced in the SLM facility for medium to high carbon springs for applications in the mechanical spring sector.

Diameter Range: Ø from 1,30 mm up to 12,00 mm

Sales: Siderurgica Latina Martin S.p.A.

Hot rolled annealed and pickled

Hot Rolled (+U)

Hot Rolled Annealed (+U+AC)

Hot Rolled (+U)

Hot Rolled Annealed (+U+AC)

Cold drawn wires and bars

Cold Drawn (+U+C)

Cold Drawn from Annealed Spheroidizing wire rod (+U+AC+C)

Redrawn annealed wire (+U+C+AC+LC)

Cold drawn with final Spheroidizing Annealing (+U+C+AC)

Cold Drawn (+U+C)

Cold Drawn from Annealed Spheroidizing wire rod (+U+AC+C)

Redrawn annealed wire (+U+C+AC+LC)

Cold drawn with final Spheroidizing Annealing (+U+C+AC)