Hot and cold forging, machining process

HOT FORGING PROCESS

Sapes S.p.A. is a company specialized in open-die forging of components with special steel grade for the automotive, agricultural and construction machinery markets.

Thanks to various automated production lines and to a solid internal organization, we ensure the highest quality standards to fulfill the customer’s requirements.

Our partnership with customers and our ability to listen to their needs have fostered and strengthened our continuous search for improvement in quality and organization.

COLD FORGING

Sapes S.p.A. is equipped with cold forging lines for the production of steering components, as tie rods and ball pins, and of engine components, as pushrods.

Many years of experience and a solid internal organization ensure the highest quality standards on the production of driving safety cold forged components.

Sapes is able to supply tie rods with rolled groove and thread. The product conformity to the customer requirements is guaranteed by a highly sensitive control device integrated in the production line.

The company complies with the UNI EN ISO 9001:2015 and the requirements of IATF 16949:2016.

MACHINING

In 1994 Sapes S.p.A. made the strategic choice to invest in the machining with the purpose of meeting the customer’s needs for a more flexible and integrated service.

Today we can supply a highly integrated production cycle which – starting from a steel bar – can provide a completely finished component ready to be assembled into the vehicle.

A dedicated production department allows us to carry out the centering, the turning, the gear cutting, the cold spline rolling, the drilling, the induction hardening and the grinding on our hot forged parts.

Thanks to various automated production lines and to a solid internal organization, we ensure the highest quality standards to fulfill the customer’s requirements of the automotive, agricultural and construction machinery markets.

HOT FORGING PROCESS

Sapes S.p.A. is a company specialized in open-die forging of components with special steel grade for the automotive, agricultural and construction machinery markets.

Thanks to various automated production lines and to a solid internal organization, we ensure the highest quality standards to fulfill the customer’s requirements.

Our partnership with customers and our ability to listen to their needs have fostered and strengthened our continuous search for improvement in quality and organization.

COLD FORGING

Sapes S.p.A. is equipped with cold forging lines for the production of steering components, as tie rods and ball pins, and of engine components, as pushrods.

Many years of experience and a solid internal organization ensure the highest quality standards on the production of driving safety cold forged components.

Sapes is able to supply tie rods with rolled groove and thread. The product conformity to the customer requirements is guaranteed by a highly sensitive control device integrated in the production line.

The company complies with the UNI EN ISO 9001:2015 and the requirements of IATF 16949:2016.

MACHINING

In 1994 Sapes S.p.A. made the strategic choice to invest in the machining with the purpose of meeting the customer’s needs for a more flexible and integrated service.

Today we can supply a highly integrated production cycle which – starting from a steel bar – can provide a completely finished component ready to be assembled into the vehicle.

A dedicated production department allows us to carry out the centering, the turning, the gear cutting, the cold spline rolling, the drilling, the induction hardening and the grinding on our hot forged parts.

Thanks to various automated production lines and to a solid internal organization, we ensure the highest quality standards to fulfill the customer’s requirements of the automotive, agricultural and construction machinery markets.

Sales: Sapes S.p.A.

Wheel hubs components

Product Description

Inner and Outer rings with and w/o flange

Major Applications

Automotive (ICE, HEV, BEV, FCEV)

Light Commercial Vehicles

Off-Highway

Materials

Carbon steels

Chromium steels

Microalloy steels

Production Processes

Hot forging

Shot blasting

Machining (Turning, Cold rolling, Broaching, Drilling & Tapping)

Heat treatments (Annealing, Through hardening, Local hardening)

Product Description

Inner and Outer rings with and w/o flange

Major Applications

Automotive (ICE, HEV, BEV, FCEV)

Light Commercial Vehicles

Off-Highway

Materials

Carbon steels

Chromium steels

Microalloy steels

Production Processes

Hot forging

Shot blasting

Machining (Turning, Cold rolling, Broaching, Drilling & Tapping)

Heat treatments (Annealing, Through hardening, Local hardening)

Gears and Pinions

Product Description

Gear wheels for MT/AT/DCT/ET transmissions

Planetary Gears for differentials

Crank Gears

Sprocket Gears

Ring Gears

Major Applications

Automotive (ICE, HEV, BEV, FCEV)

Light Commercial Vehicles

Off-Highway

Industrial

Materials

Carbon steels

Case hardening steels

Production Processes

Hot forging

Shot blasting

Machining (Turning, Broaching)

Heat treatments (Annealing)

Product Description

Gear wheels for MT/AT/DCT/ET transmissions

Planetary Gears for differentials

Crank Gears

Sprocket Gears

Ring Gears

Major Applications

Automotive (ICE, HEV, BEV, FCEV)

Light Commercial Vehicles

Off-Highway

Industrial

Materials

Carbon steels

Case hardening steels

Production Processes

Hot forging

Shot blasting

Machining (Turning, Broaching)

Heat treatments (Annealing)

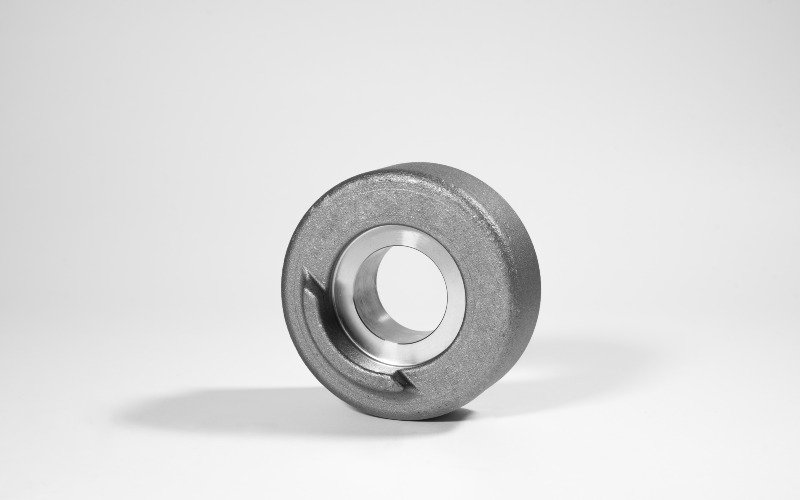

Bearing Components

Product Description

Inner and Outer rings

Major Applications

Automotive (ICE, HEV, BEV, FCEV)

Light Commercial Vehicles

Off-Highway

Industrial

Railway

Materials

Chromium steel

Production Processes

Hot forging

Shot blasting

Machining (Turning, Hard turning, Cold rolling)

Heat treatments (Annealing, Through hardening, Case hardening)

Product Description

Inner and Outer rings

Major Applications

Automotive (ICE, HEV, BEV, FCEV)

Light Commercial Vehicles

Off-Highway

Industrial

Railway

Materials

Chromium steel

Production Processes

Hot forging

Shot blasting

Machining (Turning, Hard turning, Cold rolling)

Heat treatments (Annealing, Through hardening, Case hardening)

Shafts

Product Description

Intermediate Shaft

Idler Shaft

Differential Shaft

Rotor Shaft (end piece)

Major Applications

Automotive (ICE, HEV, BEV, FCEV)

Light Commercial Vehicles

Off-Highway

Materials

Carbon steels

Case hardening steels

Production Processes

Hot forging

Shot blasting

Machining (Turning)

Heat treatments (Annealing)

Product Description

Intermediate Shaft

Idler Shaft

Differential Shaft

Rotor Shaft (end piece)

Major Applications

Automotive (ICE, HEV, BEV, FCEV)

Light Commercial Vehicles

Off-Highway

Materials

Carbon steels

Case hardening steels

Production Processes

Hot forging

Shot blasting

Machining (Turning)

Heat treatments (Annealing)

Nuts

Product Description

Hexagonal, Enko, Crown

Major Applications

Automotive (ICE, HEV, BEV, FCEV)

Light Commercial Vehicles

Off-Highway

Materials

Carbon steels

Production Processes

Hot forging

Shot blasting

Machining (Turning)

Heat treatments ((Annealing, Through hardening

Product Description

Hexagonal, Enko, Crown

Major Applications

Automotive (ICE, HEV, BEV, FCEV)

Light Commercial Vehicles

Off-Highway

Materials

Carbon steels

Production Processes

Hot forging

Shot blasting

Machining (Turning)

Heat treatments ((Annealing, Through hardening

CV Joints

Product Description

Costant Velocity Joint

Major Applications

Automotive (ICE, HEV, BEV, FCEV)

Materials

Carbon steels

Production Processes

Hot forging

Shot blasting

Product Description

Costant Velocity Joint

Major Applications

Automotive (ICE, HEV, BEV, FCEV)

Materials

Carbon steels

Production Processes

Hot forging

Shot blasting

Undercarriage Rollers

Product Description

Lower and Upper roller supports

Major Applications

Off-Highway

Materials

Carbon steels

Microalloy steels

Production Processes

Hot forging

Shot blasting

Machining (Turning)

Product Description

Lower and Upper roller supports

Major Applications

Off-Highway

Materials

Carbon steels

Microalloy steels

Production Processes

Hot forging

Shot blasting

Machining (Turning)

Other Applications