Carbon steels for drawing, wires, P.C. wire and mechanical springs

They consist of steels used in many industrial applications and can be subjected to reduced or high percentages of drawability and have suitable surfaces for subsequent galvanic treatments. Our casting techniques guarantee restricted analytical dispersions, low concentration of S and P, non-metallic inclusion content and controlled axial segregation of the carbon. Careful control of the rolling and cooling parameters (Stelmor bed) guarantees the achievement of the mechanical characteristics and the degree of drawability required by customers.

Steel grade

| Steel grade | Corresponding standard | Average chemical composition | ||||||

|---|---|---|---|---|---|---|---|---|

| Werkstoff | ORI Martin | C | Mn | Si | Cr | V | ||

| C | C60D2 | 1.1228 | MC6001 | 0,60 | 0,60 | 0,20 | - | - |

| C68D2 | 1.1232 | MC6801 | 0,68 | 0,60 | 0,20 | - | - | |

| C70D2 | 1.1251 | MC7201 | 0,70 | 0,60 | 0,20 | - | - | |

| C80D2 | 1.1255 | MC8201 | 0,80 | 0,60 | 0,20 | - | - | |

| C86D2 | 1.1265 | MC8501 | 0,86 | 0,60 | 0,20 | - | - | |

| C92D2 | 1.1282 | MC9201 | 0,93 | 0,60 | 0,20 | - | - | |

| Cr | C80+Cr | MC8001 | 0,80 | 0,60 | 0,20 | 0,20 | - | |

| Cr V | C80+CrV | MC8002 | 0,82 | 0,75 | 0,22 | 0,25 | 0,07 | |

Products

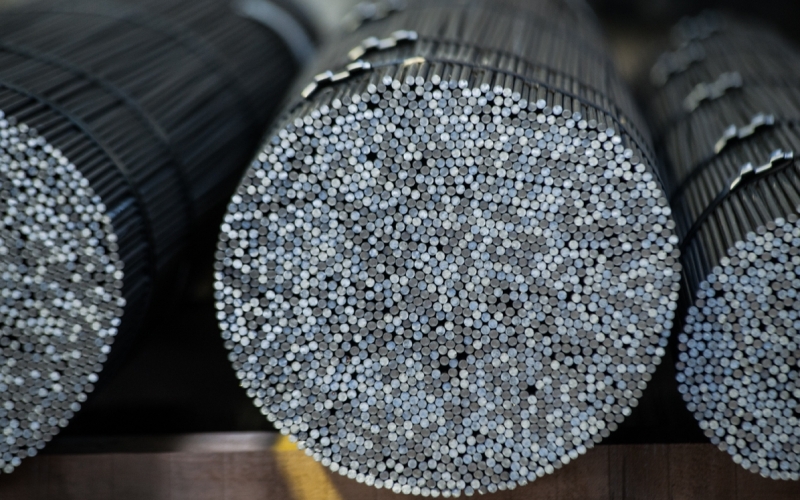

Wire rod

Rolling takes place at a controlled temperature using the very latest technology. This allows a smaller grain size to be obtained together with a more fine and even structure. Optimal characteristics for subsequent use in drawing and cold moulding in addition to a higher degree of globularisation after the annealing process.

Rolling takes place at a controlled temperature using the very latest technology. This allows a smaller grain size to be obtained together with a more fine and even structure. Optimal characteristics for subsequent use in drawing and cold moulding in addition to a higher degree of globularisation after the annealing process.

Sales: ORI Martin S.p.A.

Sales: ORI Martin France Sarl

Sales: ORI Martin Deutschland GmbH

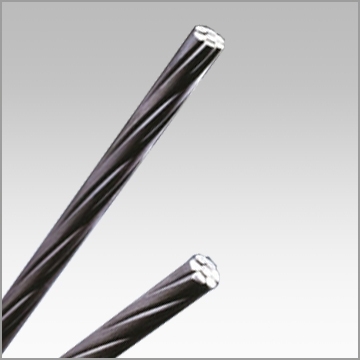

PC Strand - 7 wire

PC Strand consists of a group of seven cold drawn wires having a central wire (core wire) around which are helically spun six wires in one layer and with uniform pitch. PC Strand is mostly intended for the construction industries to produce precast concrete elements, rock & soil anchors, concrete poles as well as for pre-stressing and post-tensioning applications.

PC Strand consists of a group of seven cold drawn wires having a central wire (core wire) around which are helically spun six wires in one layer and with uniform pitch. PC Strand is mostly intended for the construction industries to produce precast concrete elements, rock & soil anchors, concrete poles as well as for pre-stressing and post-tensioning applications.

PC Strand - 2&3 wire

Established in 1963, Siderurgica Latina Martin focuses on manufacturing PC Strand (2 & 3 wires) in accordance with the most recognized international standards.

Siderurgica Latina Martin turns High Carbon Wire Rod into PC Strand (2 & 3 wires) through an integrated manufacturing process starting from in-house Acid Pickling & Pre-Coating, Cold Wire Drawing, Stranding, Thermo-Mechanical Process to Rewinding & Packaging.

2 & 3 Wire Strand consists of a group of 2 & 3 high tensile strength cold drawn wires spun together in helical form over a theoretical common axis in one layer with uniform pitch.

2 & 3 Wire Strand is widely used in precast concrete elements and concrete poles.

Additional configurations of 2 & 3 wire PC Strand can be produced on demand.

Diameter Range: 2-wires: 4,50 mm | 3-wires: 4,85 mm to 8,60 mm

Tensile Strength Range: 1770 Mpa to 2160 Mpa

Coil Weight: 190 kg to 3.000 kg

Established in 1963, Siderurgica Latina Martin focuses on manufacturing PC Strand (2 & 3 wires) in accordance with the most recognized international standards.

Siderurgica Latina Martin turns High Carbon Wire Rod into PC Strand (2 & 3 wires) through an integrated manufacturing process starting from in-house Acid Pickling & Pre-Coating, Cold Wire Drawing, Stranding, Thermo-Mechanical Process to Rewinding & Packaging.

2 & 3 Wire Strand consists of a group of 2 & 3 high tensile strength cold drawn wires spun together in helical form over a theoretical common axis in one layer with uniform pitch.

2 & 3 Wire Strand is widely used in precast concrete elements and concrete poles.

Additional configurations of 2 & 3 wire PC Strand can be produced on demand.

Diameter Range: 2-wires: 4,50 mm | 3-wires: 4,85 mm to 8,60 mm

Tensile Strength Range: 1770 Mpa to 2160 Mpa

Coil Weight: 190 kg to 3.000 kg

PC wire

PC Wire is supplied either smooth or indented and it is packed and delivered either in coils or in bundle of straight cut-to-length bars. PC Wire in straight cut-to-length bar is used to produce railroad sleepers whereas PC Wire in coils is mostly used as reinforcement in concrete pre-stressed elements.

PC Wire is supplied either smooth or indented and it is packed and delivered either in coils or in bundle of straight cut-to-length bars. PC Wire in straight cut-to-length bar is used to produce railroad sleepers whereas PC Wire in coils is mostly used as reinforcement in concrete pre-stressed elements.

Medium-High carbon wire

Drawn wire is produced in the SLM facility for medium to high carbon springs for applications in the mechanical spring sector.

Diameter Range: Ø from 1,30 mm up to 12,00 mm

Drawn wire is produced in the SLM facility for medium to high carbon springs for applications in the mechanical spring sector.

Diameter Range: Ø from 1,30 mm up to 12,00 mm